DI Pipe Spring

The National Leader Powering 70% of India’s Ductile Iron Pipe Production

At Hinglaj Spring Industries, we don’t just make springs—we engineer the reliability required for centrifugal casting. With 14 years of specialized niche experience, we are the primary choice for India's largest DI Pipe plants, providing mould springs that withstand extreme thermal stress and mechanical vibration.

Precision Engineering for Every Diameter

Our high-accuracy springs are built to fit all standard centrifugal casting machines seamlessly:

- Small Series: DN 100 | DN 150

- Medium Series: DN 200 | DN 250 | DN 300

- Large Series: DN 400 and above (Custom Heavy Duty Springs)

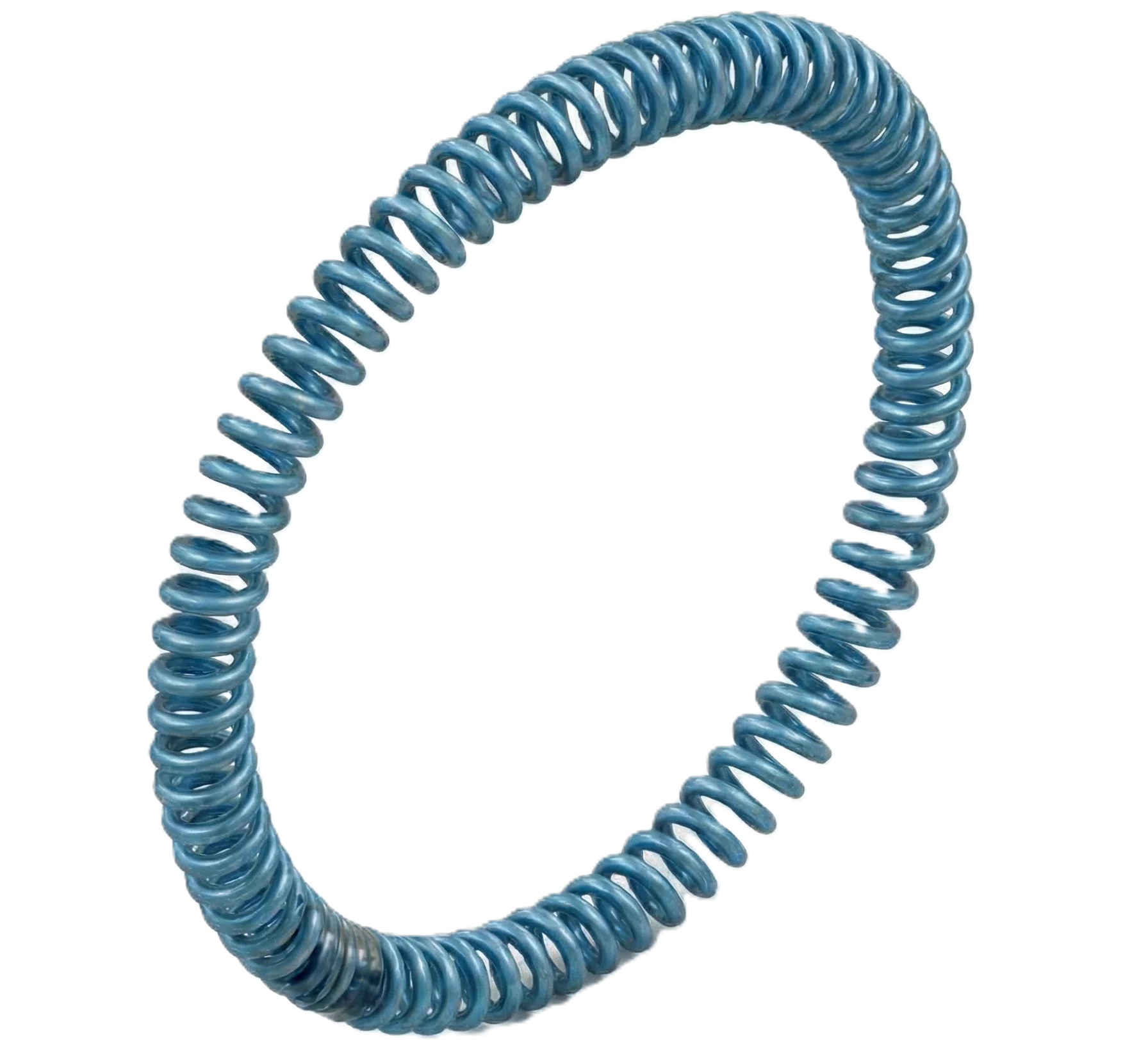

The Hinglaj Advantage

- Market Authority: We proudly supply 70% of the Indian market, a testament to our quality spring manufacturing and trust.

- Extended Service Life: Engineered for "Long Durability Life-Expand," reducing your plant’s downtime and spring replacement costs.

- Zero-Defect Casting: Tight manufacturing tolerances ensure uniform spring tension, preventing casting errors in the pipe formation.

- Premium Alloys: Manufactured from high-grade SAE 9254 and EN 47 to maintain "spring-back" under intense heat cycles.

Technical Excellence & Quality

- Advanced Manufacturing: Precision Hot/Cold Coiling tailored to wire diameter.

- Surface Treatment: Professional Shot Peening for maximum fatigue resistance.

- Rigorous Testing: 100% load testing to meet and exceed OEM standards.

- Trusted by 70% of India’s DI Pipe manufacturers. Let our springs power your production line.